IBC DRUM FILLING MACHINE

Model No.: ADF-1200L1

Filling Material: lubricating oil/Resin/ Engine oil

Filling Weight: 1000kg/IBC DRUM

Filling Capacity: 1000L IBC DRUM

Filling Accuracy: ±0.1% F.S. (Accuracy depends on suitable adjustment of slow feeding and the stability and consecutiveness of liquid to spray gun

Filling Speed: 10 IBC DRUMS/hour (Depend on previous speed of feeding material, the previous speed of liquid must be 300L/MIN.)

Measure Method: Two-section Feed Control, Filling into drum on above liquid level

Material Connector: DN40 Rapid Flange Connector (Pressure of liquid feeding should less than 0.6MPa)

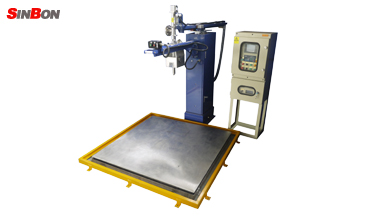

EQUIPMENT DESCRIPTION

Electric Weighing Scale with Roller Conveyor

Weighing Range: 1200kg x200g

Weighing Table Size: 1500mm X1500mm

LOVOSC LP7110 Load Cell for pieces

JB-05 Load Cell junction box

Painted Steel Platform

Roller Conveyor with no motor driven

Weighing Area Size:1500mm(L)x1500mm(W)

Material of Machine Body: Painted Steel

Installation Mode: On Ground

Automatic Liquid Filling Machine

Φ1 1/2” FB type Two Stages pneumatic Filling Spray Gun (Material of Spray Gun is SUS 304, Sealing Material: polyvinyl fluoride), Attached Φ1 1/2” rapid connector for feeding material, which used for change material, fast disassemble.

Three-section infeed control, there is a foot valve at head of filling gun to improve filling accuracy and avoid rest of liquid overflow

Gas-collection hood used to collect flue gas, stainless steel 304 material

Offer anti-leak cup, stainless steel 304 material

Manual adjust spray gun height

Equipped with automatic promotion and demotion cylindersEquipped with base of filling nozzle (Material: Painted stainless steel)

Included Anti-explosion pneumatic parts (pneumatic parts brand is AIRTAC)

Automatic Controller

Wall-hung type Control Box

ST510 Weighing Controller

MCGSTPC TPC7062Ti Operation Interface

FATEK FBS PLC programming control (Including RS232 modular)

Two-section liquid infeed weight control (fast-slow)

Automatic Stop and Alarm when no liquid

OTHER REQUIREMENT

Buyer should install the machines by themselves and seller can give them guide; quotation doesn’t include installation costs.

Buyer should prepare soft pipe and flange to connect with our machines to infeed liquid; Buyer should prepare pump to supply liquid to our machine and it should has reflux device; buyer should prepare separate power source AC380V, 3Phase/AC220V;1Phase; 50Hz; 20A and 4-6kgf/cm2 compressed air.

Auto Filling Capping Machine for spray bottles

More>>