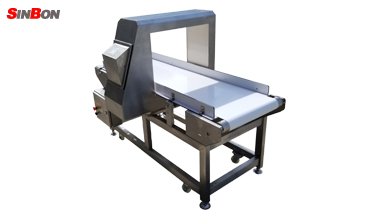

Metal detector for detecting all metals mixed in garments

FEATURES

New designed detection coil technology, shorter conveyor length to save installation space

Stainless steel structure, laser cutting technology, appearance looks beautiful and smart

Stronger stainless steel structure, obey rules of hygiene and food safety and easy to clean

Compact conveyor design, easy to assemble and disassemble

Double Channels metal detection coils and using micro controller

Modular Design meet with requirement of custom made, ensure after sales service simple

Imported high quality components and parts to ensure machine's stability

Anti-interference ability strong, suitable for bad working environment

Automatic rejector for option including air pusher, flapper, swing arm etc.

Detecting all metals including ferrous, non-ferrous, stainless steel metals mixed in products

APPLICATION

Used to detect broken needles, shoe nail, iron wire and other metal pieces left inside of toys,

garments, shoes etc.

It can be used to detect carton box etc.

SPECFICATION

Model No.: YS-6035A

Theory: Balance Coil

Aperture Size: 600mm(W)X350mm(H)

Sensitivity without product's effect: Fe ≥Φ2.0mm; Non-Fe≥Φ2.5mm; SUS304≥Φ3.0mm

Max. Detection Width: 560mm

Max. Detection Height: 300mm

Belt Width: 500mm

Belt Material: PVC

Belt Speed: 20m/min.

Power Source: AC220V;50Hz;1P

Conveyor Length: 1500mm

Conveyor Height: 700-800mm

Max. Loading Weight: 10kg (Heavy products should custom made)