Advantages

Automated production with high production efficiency, max. output up to 600 pails/hour

Large-flow magnetic gear pump metering with fast dispensing speed and high filling accuracy

5-30L pails universal design, realizing one machine for multiple size of pails filling

Innovative design ensures that the hardware is quickly switched into place when changing different size of pails, saving time and improving efficiency.

All the parameter setting finished on touch screen, save as recipe for fast change product

Automatic Pails Rotator

The automatic pails rotator main function is automatically tracking the position of the pails mouth, rotate the pails to ensure all the pails mouth in the same direction to ensure filling nozzle can insert to pails mouth in next process.

The automatic pails rotator is composed of a chain plate conveyor, a servo driving belt conveyor for rotate the pails, a pails grabbing manipulator, and a parallel mechanism.

The automatic pails rotator realizes automatic pails feeding, automatic tracking pails mouth, automatic grabbing of empty pails and parallel move to the conveyor of the filling machine

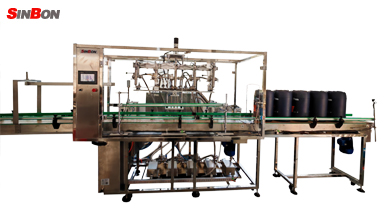

Auto Pails filling machine

Touch screen, PLC and servo system are used to realize the automatic control of the whole machine

Five sets of high-flow servo-driven gear pumps for precise metering and rapid dispensing

Five sets of big diameter pneumatic diving nozzles

The up and down of the nozzle is driven by a servo motor, and the nozzle waiting position is set according to the height of the pails to save the action time of the nozzle and improve production efficiency

The nozzle is equipped with a dedicated line for CIP circulation cleaning and is equipped with manual valve control.

It is equipped with a drip tray to prevent liquid from falling to the conveyor

The adjustment of left and right positions of the nozzles is controlled by a diamond-shaped mechanism, and the automatic alignment of the nozzle with pails mouth can be realized by simply rotating the handwheel when change products, making it easy to achieve rapid product changing

Equipped with a pails mouth positioning device, it automatically detects the position of the pails mouth, and if there is a pails mouth misalignment, the filling is automatically paused and waiting for manual inspection

Equipped with a pails mouth guide rail, all pails mouths are guided to be conveyed to the filling station in the same direction

All soft hoses are food grade hoses and can also be supplied with stainless steel explosion-proof hoses for option.

The whole machine is equipped with a protective cover, which is safer for personnel and equipment is more beautiful

The functions include production capacity statistics, recipe storage, IO visualization, Pails blocking detection, CIP cleaning, residual liquid empty clear function, interlock control, etc

The whole machine is made of stainless steel 304 material, which is hygienic and easy to clean

Tank (optional)

Tank size 100-1000L is optional, if the user does not have a tank, it can be ordered for option. The filling machine does not need to be equipped with a tank and can automatically suck liquid from the user's turnover tank.

Equipped with a spherical spraying device, the inner wall of the storage tank can be cleaned by high-pressure spray cleaning fluids when performing CIP cleaning.

Equipped with a centrifugal pump to perform CIP cycle cleaning,

Equipped with a liquid level detection device to automatically control the user's liquid feeder to automatically feed liquid to tank

Pneumatic ball valves control the opening and closing of the feeder

The bottom of the tank is equipped with a manual discharge valve, which is convenient for discharging liquid in the tank after cleaning.

The discharge pipes are all stainless steel and are connected by quick-release snaps

Stainless steel material is easy to clean

Outfeed Conveyor

After the filling is completed, the finished product is move to outfeed conveyor, on which the capping can be completed by hand (or with automatic capping machine here)

Equipped with pails blocking detection sensor, if blocked, the rotator conveyor will stop

Ultra-wide chain plate heavy loading conveyor design

Specification

Model No. | DLF200-5QS |

Filling range | 5-30L |

Capacity | 300-600 barrels/hour |

Pump type | High flow magnetic gear pump |

Pump flow rate | ≤ 120L/min/pump (water). |

Filling accuracy | ≤±0.3% |

Pump Quantity | 5 sets |

Nozzle size | Φ40mm |

Pails Size | 5-30L drum |

Power Source | AC380V; 50/60Hz; 3P |

Air source | 5-6Kg/cm²; 0.3m³/min. |

System control | PLC+servo system |

Display | Touch screen |

Chain width | 500mm |

Dimension | 7400x1200x2350mm |

Packing Size | Pails Rotor: 2250x1250x2040mm Net/Gross Weight: 300kg/385kg Pails Filling Machine: 3810x1250x2250mm Net/Gross Weight: 600kg/720kg Tank & Outfeed conveyor: 2150x1650x1680mm Net/Gross weight: 320kg/400kg |