Key Features

7-inch touch screen display and PLC system control

Product parameters setting on the touch screen

60 products parameters preset, easy to recall and edit

One-button start, simple operation

With counter statistics function

Magnetic gear pump measures filling volume

Diving filling nozzle is inserted inside of bottle for filling

The left and right position and height of the nozzle are adjustable

Digital speed regulator controls the liquid flow rate

Electronic speed regulator controls the conveyor speed adjustment

With bottle collection platform for temporary bottle storage

Fully automatic quantitative filling, no bottle no filling

Front and rear bottle blocking cylinders are equipped with safety protection cover

The left and right positions of the front and rear bottle blocking cylinders are adjustable

Two one-way valves prevent liquid dripping or backflow

Compatible with multiple size of containers

The main structure based on 2mm thickness stainless steel 304

Chinese and English language operating system

Advantages

Small footprint, Lightweight and easy to move

Multi-head filling with high output and high speed

Fully automatic filling saves manpower

Miniaturized fully automatic filling system

Easy to operate without professional training

Easy to maintain and worry-free after-sales

Application

This machine is suitable for quantitative filling or filling of various easy-flowing liquids such as perfume, essential oil, edible oil, mineral water, potion, soy milk, milk, liquor, vinegar, beverages, etc.

This machine is suitable for quantitative filling of liquids in food, medicine, daily chemicals and other industries

Specification

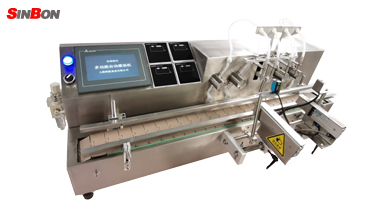

Model No. | YH100-4H (Desktop) |

Filling Range | 5-3000ml |

Filing Accuracy | ±0.5-1.0% |

Flow Rate | ≤ 3L/min./Pump |

Capacity | 150ml: 0-30BPM |

Pump Type | Magnetic Gear Pump |

Pump Material | Pump material is SUS304, Gears are peek |

Nozzle Type | Diving Nozzle Dia. 8mm |

Nozzle Quantity | 4pcs |

Diving Depth | ≤45mm |

Belt Width | 80mm |

Conveyor Length | 1400mm |

Dimension | 1480(L)x450(W)x370mm(H) |

Air source | 0.4-0.7Mpa |

Power source | AC220V; 50Hz;1Phase; 0.3kw |

Working Mode | Auto/Manual |

Packing Size | L1540xW690xH540mm |

Weight | N.W.: 60kg G.W.: 90KG |

Special Material Application

Special Material | Application |

Easy Flow liquid like water | Yes |

Foaming Liquid | Yes |

Corrosive Liquid | Yes (Except for strong acid and strong alkali liquids) |

Semi-fluid | No (choose other model) |

Liquid with Particles | No (choose other model) |

Remarks: Special material maybe need change machine parts