APPLICATION

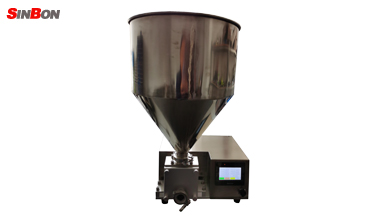

DLF-500 series automatic quantitative injection machine is an advanced equipment that can accurately quantify and automatically inject paste, semi-fluid and fluid raw materials. Suitable for use in bakeries, cake shops, western restaurants, coffee shops, food processing plants, etc. Filling cores for various foods such as bread, cakes, puffs, etc., use hollow needles to insert the inside of the product and directly inject raw materials into the product without damaging the appearance of the product; used to coat the product such as cake with cream or other Pastry decoration; for quantitative filling of products such as filling honey to bottles. Automatic quantitative filling machine can improve production efficiency and uniform product quality. It is an essential equipment for bread, cake and dim sum shops.

FEATURES

Touch screen operation makes work easier, faster and more accurate

The basic functions include manual mode and automatic mode: in manual mode, the operation can be freely controlled to start and stop the injection; in automatic mode, both single-time quantitative filling and automatic continuous quantitative filling can be set at a certain interval.

The equipment is equipped with a suction function to avoid material dripping

Through the mode switch button, you can easily switch back and forth between quantitative injection mode and continuous injection mode.

Three control methods include: foot pedal (hand grip) control, photoelectric sensor control, external signal control for option

Optional different filling nozzles can be used for quantitative filling, coating, decorating and other purposes

Optional automatic conveying system to form online automatic injection equipment for automatic production

Complete stainless steel structure, compact and easy to move

SPECIFICATION

Model No. | DLF-500 |

Pump Type | Gear Pump |

Pump Material | PE(PTFE for option) |

Hopper Size | 20L(5L,10L,30L,40Lfor option) |

Power source | AC220V;50Hz;1P (AC110V;60HZ;1P for option) |

Dimension | 400x400x670mm(20L hopper) |

Net/ Gross weight | 25KG/41KG |

Remark:

1. Filling accuracy is affected by the following factors:

1) Flowability of raw materials: The better the flowability, the higher the accuracy; the worse the flowability, the lower the accuracy.

2) The viscosity of raw materials: the lower the viscosity, the higher the accuracy; the higher the viscosity, the lower the accuracy.

3) Injection speed: the lower the injection speed, the higher the accuracy; the higher the injection speed, the lower the accuracy.

4) Injection pipe length: The shorter the injection pipe length, the higher the accuracy; the longer the injection pipe length, the lower the accuracy.

5) Injection pipe diameter: The smaller the injection pipe diameter, the higher the accuracy; the larger the injection pipe length, the lower the accuracy.

2. We accept custom made, please contact with sales department